Infrastructure

The infrastructure is divided in four areas, three of them related to testing at different scales and one related to computing facilities:

1. Laboratory equipment

2. Test rigs

3. Pilot plants

4. Computation cluster

This infrastructure has allowed the group to carry out more than 15 international and 20 national research projects, and this has been and continues to be an attraction for many researchers who come to GREiA to carry out part of their research.

Laboratory equipment:

DSC – Differential Scanning Calorimetry

Thermal processes analysis (Tg, Cp, h)

Temperature range: from -25 ºC to 500 ºC

Compact climatic chamber

Simulates various temperature and humidity environment

Temperature range: from -50 ºC to 500 ºC

Home-made test box

Temperature cycles for samples up to 19x19x3 mm

Temperature range: from 5 ºC to 45 ºC

Thermal cycler

Temperature cycles

Temperature range: from 4 ºC to 105 ºC

Vacuum reactors

Home made system. Key features include:

- Several 5 L glass reactor that allows visual inspection

- Heating unit

- Evaporator

- Vacuum pump

- Sensors and data logger

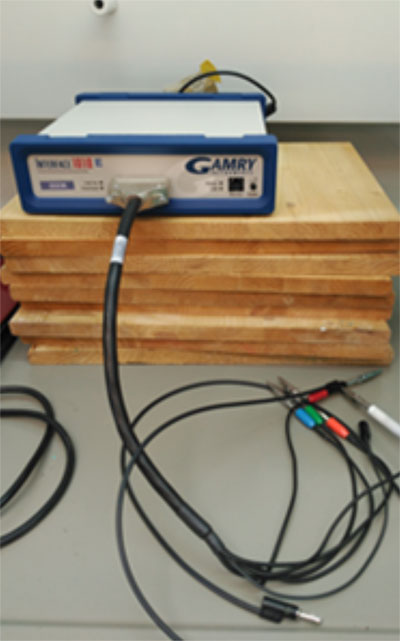

Electrochemical impedance spectroscopy (EIS) for corrosion testing

It is a full-featured potentiostat capable of performing all techniques, including electrochemical impedance spectroscopy. Key features include:

- Maximum applied current: ±1 A

- Maximum applied potential: ±12 V

- EIS: 10 μHz – 2 MHz

TGA – Thermogravimetric analysis

Stare system TGA Mettler ToledoTemperature range: from 20 ºC to 1100 ºC

Vacuum reactors

Hot Disk TPS 2500 S

It handles sub-millimeter-thick bulk samples, has a thermal conductivity range of 0.005 to 1800 W/m·K, and accommodates temperatures from cryogenic to 1000 ºC

High-temperature chamber furnace

NABERTHERM LH 216/12

Chamber furnace LH 216/12 with multi-layered insulation of light refractory bricks and special backup insulation, with fresh air fan to accelerate the cooling times

Maximum temperature: 1200 ºC

High-temperature chamber furnace

NABERTHERM LH 60/12

Chamber furnace LH 60/12 SW with multi-layered insulation of light refractory bricks and special backup insulation, with scale to measure weight reduction during annealing

Maximum temperature: 1200 ºC

Nitrogen generator

NG5000A Peak Scientific

The NG5000A carbon molecular sieve generator delivers ultra-high purity nitrogen at trace detection limits through Pressure Swing Adsorption technology at flows of up to 5 L/min

Suitable for applications such as GC, DSC, DMA or any applications requiring ultra-high purity nitrogen

Maximum operating temperature: 25 ºC

Test rigs:

Latent heat testing rig

Testing and characterization of the behaviour of latent heat TES system for mid-low temperature applications

Temperature range: from -20 ºC to 100 ºC

Sensible heat tank

Testing the behavior (thermal stratification and heat losses) of a 500 liters domestic hot water tank with vacuum insulation

Temperature range: from 5 ºC to 90 ºC

Thermochemical testing rig

Testing and characterization of the water uptake of sorbent materials in a close sorption system

Temperature range: from 20 ºC to 120 ºC

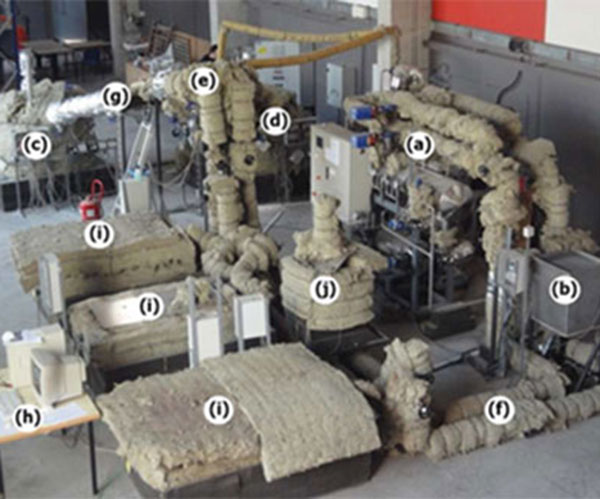

Pilot plants:

Pilot plant for testing of TES technologies and systems in buildings: Connected to two different real buildings (residential and non-residential), with PV, Fresnel collectors, ORC, PCM, and sorption system.

Pilot plant for testing of TES in buildings: materials, HVAC systems with TES, geothermal storage, PCM storage, TCM storage.

Pilot plant that allows to compare the use of different control strategies in thermal energy system with TES installed in building applications.

Pilot plant for testing of an innovative seasonal thermal energy storage (STES) unit with a novel storage material and creative configuration.

Computation cluster: